Plastic simply does not deteriorate in landfills, and Jeremy Lang who grew up in Yorkton and attended the Yorkton Regional High School thinks there is an alternative.

"I read somewhere that pretty much every piece of plastic that has ever been made still exists today, and less than eight per cent of plastic is recycled," he said. "This made me have a closer look at the amount of plastic we use and potential alternatives."

Lang said there is an option.

"Bioplastic is becoming an eco-friendly alternative to conventional plastic, but its uses have been limited to single use items, such as utensils, due to its brittle characteristics," he said. "Historic research has shown that flax fibre could be used to strengthen conventional plastic, but there was no research on using flax fibre to strengthen bioplastic. I wanted to see if flax fibre and shive could be added to bioplastic to increase its strength and make it applicable to more consumer products."

Thinking about flax straw was a natural for Lang who went to the University of Saskatchewan where he received his Bachelor of Science in Agriculture in 2000.

"Saskatchewan is one of the largest oil seed flax producers in the world and I always found it odd that we often burn the flax straw (and flax fibre) because the fibre makes it difficult to manage in the field, yet they grow flax specifically for the straw and fibre in Europe," he said.

"There has been a lot of research conducted at the University of Saskatchewan to attempt to find ways to make better use of the flax straw in Saskatchewan, but no consumer products have been produced here to date. I wanted to try to find a way to use our flax straw in a consumer product."

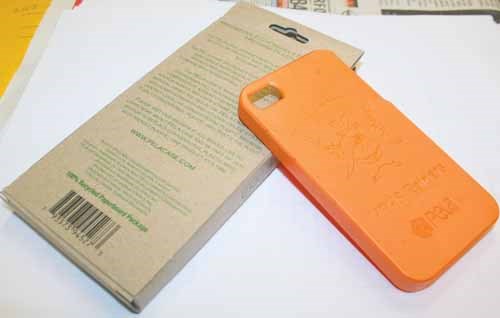

That desire has led to the creation of an environmentally friendly alternative case for the Apple iPhone.

"I selected the Apple iPhone 4 Case as the first consumer product to try to manufacturer due to its relatively simple design, the size of the market place and the fact that conventional plastic iPhone 4 cases last for hundreds of years, yet the average person only keeps their smart phone for 18 months," offered Lang.

The idea is one Lang has been working on for a couple of years.

"I came up with the idea for creating an eco-friendly Apple iPhone 4 case from flax fibre and bioplastic in the summer of 2010, and I began talking with U of S researchers and applying for research and development funding shortly after," said Lang who has been working as an Environmental Consultant at Stantec Consulting Ltd. in Saskatoon as since 2001.

Lang received partial R and D (research and development), and marketing funding from the Canadian Agricultural Adaptation Fund (administered by the Agriculture Council of Saskatchewan) and the Saskatchewan Agri-Value Initiative Fund (administered by Saskatchewan Ministry of Agriculture's Growing Forward program) in late 2010 and early 2011 and had his first PELA Case ready for market in September of 2011.

Lang said there were some challenges to getting the case to the marketplace.

"It has been a challenge getting the formula to a consistent salable form and our formula has changed numerous times over the last year," he said. "We are continually trying to push the performance and eco-friendly aspect of our formula and we are hoping to have a backyard compostable version of the PELA case available in the future.

"We use Saskatchewan and Manitoba flax straw that is processed at Biolin Research in Saskatoon and at SWM International in Manitoba. The resin, or bioploymer, we use is made from plants and manufactured in the United States."

The result is a case which doesn't have to last forever in a landfill.

"The eco-friendly PELA case is compostable in industrial composting facilities," said Lang. "It is made from plants instead of crude oil so it helps to decrease our dependence on non-renewable resources and it does not contain bio-accumulative toxic chemicals."

And farmers can benefit too.

"It also provides another potential market for producers flax straw fibre," he said.

The PELA case is manufactured in Saskatoon and it is currently being sold in Saskatchewan in the SaskTel Corporate Stores. It is also available at the souvenir shop at YRHS in the city.

"We have had customers from Canada, USA, Europe, Australia and South America purchase the PELA case through our website (www.pelacase.com)," said Lang, adding new products are in development.

"We plan to have an Apple iPad PELA case ready this summer, along with some new formula and colour combinations," he said. "We are also exploring the use of our formula in other consumer products."